V-Serie

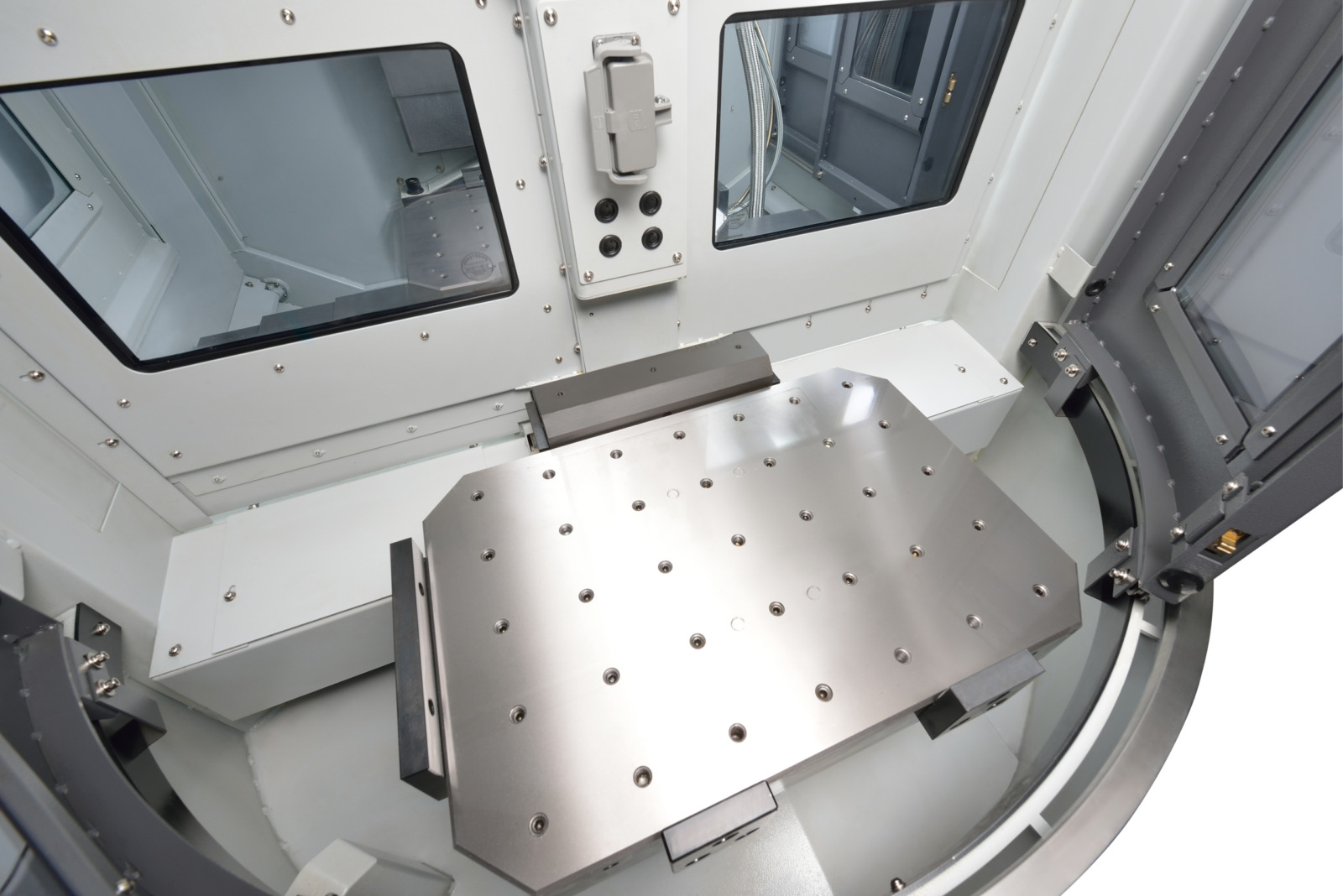

Die vertikalen Bearbeitungszentren der Bridgeport® V-Serie sind Maschinen einer neuen Generation. Bei diesen Maschinen handelt es sich um volldigitale, Hochqualitäts-Werkzeugmaschinen, die für maximale Leistungsfähigkeit beim Einsatz in der Auftragsfertigung, OEMs, in der Luft- und Raumfahrtindustrie, der Fahrzeugtechnik, bei Energieerzeugern und vielen anderen anspruchsvollen Märkten entwickelt wurden.

| V480 | V480 APC | V710 | V1000 | |

| Motorleistung Hauptspindel |

5.5 / 7.5 kW (Fanuc) (Contin./ 30 min) |

5.5 / 7.5 kW (Fanuc) (Contin./ 30 min) |

5.5 / 7.5 kW (Fanuc) (Contin./ 30 min) |

15 / 18.5 / 22 kW |

| Spindeldrehzahl (max) |

10.000 min-1 (Option: 12.000/15.000 min-1) |

10.000 min-1 (Option: 12.000/15.000 min-1) |

10.000 min-1 (Option: 12.000/15.000 min-1) |

10.000 min-1 (Option: 12.000/15.000 min-1) |

| Verfahrwege X, Y, Z | 480 mm x 400 mm x 430 mm | 480 mm x 400 mm x 430 mm | 710 mm x 400 mm x 430 mm | 1,020 mm x 610 mm x 610 mm |

| Aufspannfläche | 600 mm x 400 mm | 600 mm x 400 mm | 800 mm x 400 mm | 1,200 mm x 600 mm |

| Aufnahmekegel | # 40 BIG-PLUS | # 40 BIG-PLUS | # 40 BIG-PLUS | # 40 BIG-PLUS |

| Werkzeugwechsler | 20 Werkzeuge | 20 Werkzeuge | 20 Werkzeuge | 30 Werkzeuge |

|

CNC Steuerungen Option |

Fanuc Oi-MF Siemens 828D |

Fanuc Oi-MF Siemens 828D |

Fanuc OI-MF Siemens 828D |

FanucOi-MF Siemens 828D Heidenhain TNC 620 Mitsubishi M80 |

| Maschinengewicht (ca.) | 3,800 kg | 3,520 kg | 3,907 kg | 7,000 kg |

| Maschinenabmessung (L x B x H) | 2,716 mm x 2,659 mm x 2,572 mm | 1,676 mm x 2,718 mm x 2,797 mm | 2,572 mm x 2,827 mm x 2,659 mm | 2,673 mm x 3,048 mm x 2,850 mm |

Bridgeport’s high quality, highly specified V-Series Vertical Machining Centers (VMCs) are extremely compact and rugged mills; developed for applications that require both the utmost in speed and accuracy. V-Series machines are equipped with industry-leading features that enable speed, power, accuracy, and durability–all in a compact design and at an affordable price. V-Series Vertical Machining Centers are rigid and reliable, consisting of a robust, one-piece cast iron base, heavy-duty linear guideways and ball screws, and many value-added standard features including:

- Heavy-duty dual-wound spindle motor

- 40-PSI coolant supplied through circular flushing coolant ring at spindle face offering 360º coverage of the cutting tool

- Chip conveyor interface

- Swing-out CNC control panel

Choose from the numerous productivity options for a truly versatile machine–all with the level of quality that you would expect from any Bridgeport product.

FANUC 0iMD

- 4" Farb-LCD

- Handbuch Guide 0i

- Dynamische Grafikanzeige

- Teilprogrammspeicherlänge 1280m / 512 Kbyte

- MDI (Manuelle Dateneingabe) Betrieb

- Anzeigeeinheit mit PCMCIA-Schnittstelle

- USB-Anschluss

SIEMENS 828D

- 4″ TFT-Farbdisplay

- USB 2.0, RJ45 Ethernet, CF-Karte Schnittstellen

- ISO-Programmierung, Programm GUIDE

- ShopMill

- Werkzeug- und Werkstückvermessung

FANUC Oi-MD

- 10,4“ LCD Monitor

mit einer Vielzahl an Funktionen

SIEMENS 828D

- mit Shop Mill 10,4“LCD Monitor mit einer Vielzahl von Funktionen

Mitsubishi M 80

- 15“ Touch Screen

Heidenhain TNC 620

- 15“ Color Display

mit einer Vielzahl an Funktionen

Bei den auf der CNC-Steuerung angebotenen Funktionen zur Dialogprogrammierung handelt es sich um das Standardprodukt des Herstellers der CNC-Steuerung, das möglicherweise nicht alle Maschinenfunktionen vollständig unterstützt. Es wird empfohlen, dass der Endbenutzer die Dokumentation des Steuerungssystems zu Rate zieht oder sich mit dem Steuerungshersteller in Verbindung setzt, um weitere Details zur Verwendung oder Anpassung zu erfahren.

Vertikale Bearbeitungszentren der V-Serie werden in unzähligen Branchen eingesetzt, darunter:

- Luft- und Raumfahrt

- Pharmazie

- Automobil

- Große Werkstätten & OEM