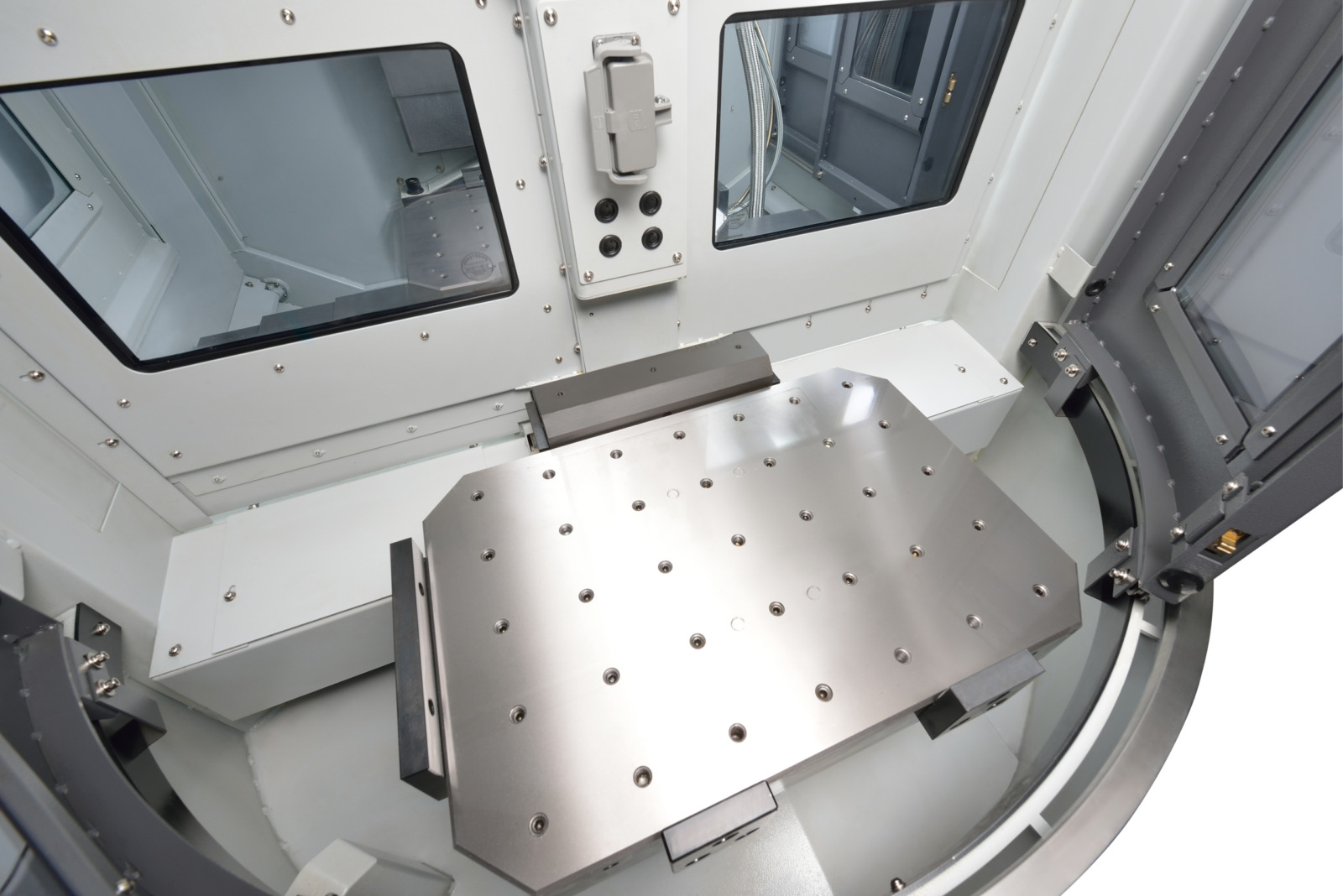

V-Series 5AX (V320, V650)

Bridgeport’s innovative technology provides superior accuracy, repeatability, a large load rating, stable accuracy, high rigidity and low friction for optimal production of small to large parts. All of the robust features are designed into a cost-effective, smaller footprint machine. Our 5-Axis vertical machining centers are developed and designed to meet the processing needs of complex parts across a wide range of industries.

| V320 | V650 | |

| Travels | ||

| X/Y/Z Axes | 510 x 610 (+/- 305) x 510 | 620 x 520 x 460 |

| B-Axis Swing Range | - | -50° ~ +110° |

| C-Axis Rotation Range | 360° | 360° |

| A-Axis Rotation Range | +30° ~ 120° | - |

| Spindle Nose to Table | 20 - 530 | 150 - 610 |

| Y-Axis Throat Distance | 628 | - |

| Table | ||

| Table Size | 320 | 650 |

| Max. Workpiece Range (Dia. x Height) |

400 x 320 | - |

| Load Capacity (Horizontal) | 150 Kg | 300 Kg |

| Load Capacity (Tilit) | - | 200 Kg |

| Load Capacity (Vertical) | 100 | - |

| T-Slots (Size x Number of Slots) |

12 x 4 | 18 x 5 |

| Spindle | ||

| Spindle Taper | 40 (BBT 40) | 40 (BBT 40) |

| Spindle Speed (Max.) | 10000 RPM | 15000 RPM |

| Spindle Transmission | Coupling (HT Spindle) | Direct Connected |

| Automatic Tool Changer (ATC) | ||

| Type | Swing Arm | Mechanical |

| Capacity | 30 | 40 |

| Tool Selection | Bi-Directional | - |

| Max. Tool Dia. (Full Drum) | 75 | 75 |

| Max. Tool Dia. (Full Drum/Adj. Pocket Empty) |

150 | 125 |

| Max. Tool Length | 240 | 250 |

| Max. Tool Weight | 7 Kg | 7 Kg |

| Servo Axis | ||

| X/Y/Z-Axis Rapid Traverse Speed | 43/43/36m/min | 36/36/36m/min |

| X/Y/Z-Axis Max. Feed Speed | 16m/min | 15m/min |

| Accuracy (ISO 230-2) | ||

| X/Y/Z Positioning (w/ Scale) | 0.004 | 0.004 |

| X/Y/Z Repeatability (w/ Scale) | 0.003 | 0.003 |

| X/Y/Z Positioning (without Scale) | 0.005 | 0.005 |

| X/Y/Z Repeatability (without Scales) | 0.004 | 0.004 |

| General Specifications | ||

| Machine Weight | ~7405 | ~8200 |

| Machine Length | ~3663mm (Including Chip Conveyor) | ~4250mm |

| Machine Depth | ~2670mm | ~4120mm |

| Machine Height | ~3195mm | ~3100mm |

Siemens Control Features

- 19″ Multi Touch Display Modular

- Integrated QWERTY Keyboard

- Ethernet Interface, 2x USB 3.0

- Processing Step Programming/Graphical

- Man-Machine Interface

- Graphical 3D Simulation

- 5-axis Imputation

- Look-Ahead of Max. 3000 Blocks

- 2D/3D Collision Avoidance

- Zero Offset 100 Sets

- Online Help Function

- CNC Internal 6MB, External Memory 10M

- Helical Interpolation

- Max of NCU Program 1000

- High-Speed Interrupt Continuous Path

- Auxiliary Functions

- Tool Life and Workpiece Count monitoring

- Network Management

- Universal Interpolator NURBS (Non-uniform Rational B-splines)

- Handwheel Overlay

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

Standard Features

- Manual Central Grease Lubrication (X/Y/Z Axes)

- Work Light

- Retention Knobs

- Spindle Taper Cleaner

- MPG Handwheel

- Ethernet Connection

- Stack Light (3 colors)

- Column Riser 150mm

Optional Features

- Automatic Central Grease Lubrication (X/Y/Z Axes)

- Transformer

- Auto Power Off

- Tool/Part Probe Pre-wiring

- Tool/Part Probe RENISHAW RMP40+RMI-Q+RTS

- Power Case Chiller

- Spindle Oil Chiller

- Spindle Circular Flushing

- Cutter Air Blast (Spindle Side)

- Coolant Through Spindle, 280 PSI (20 Bar)

- Chip Flush System

- Chip Conveyor: Hinge/Scraper/Complex Type

- Linear Optical Scale (X/Y/Z Axes)

- Front Door Auto Door with Light Curtain

Standard Features:

- DDS Spindle (with Chiller)

- BBT40

- Tool Magazine Auto Door

- Worm Gear Type B/C Axis

- Surround Tool Coolant

- Coolant Chip Flush

- Coolant Wash Gun

- Auto Central Grease Lubrication

- Automatic Power Off

- Remote MPG Handwheel

- B/C Axis Encoder

- 2 Color Stack Light (LED)

- Chiller for Power Case

Optional Features

- Chain Type Magazine ATC, 60 Tools

- Built-in Motor Type B/C Axis

- Coolant Through Spindle (CTS) 20Bar

- Air Gun

- Cutter Air Blast

- Hinge Type Chip Conveyor

- Scraper Type Chip Conveyor

- Chip Cart

- X/Y/Z Axis Linear Scale

- Part Probe RENISHAW OMP40-2+OMI-2T

- Datum Ball, RENISHAW D19

- Table Hydraulic Fixture, 4 Port

Bridgeport V-Series 5AX Vertical Machining Centers can be found serving countless industries, including:

- Aerospace

- Medical

- Mold & Die making

- Automotive

- Advanced Industires