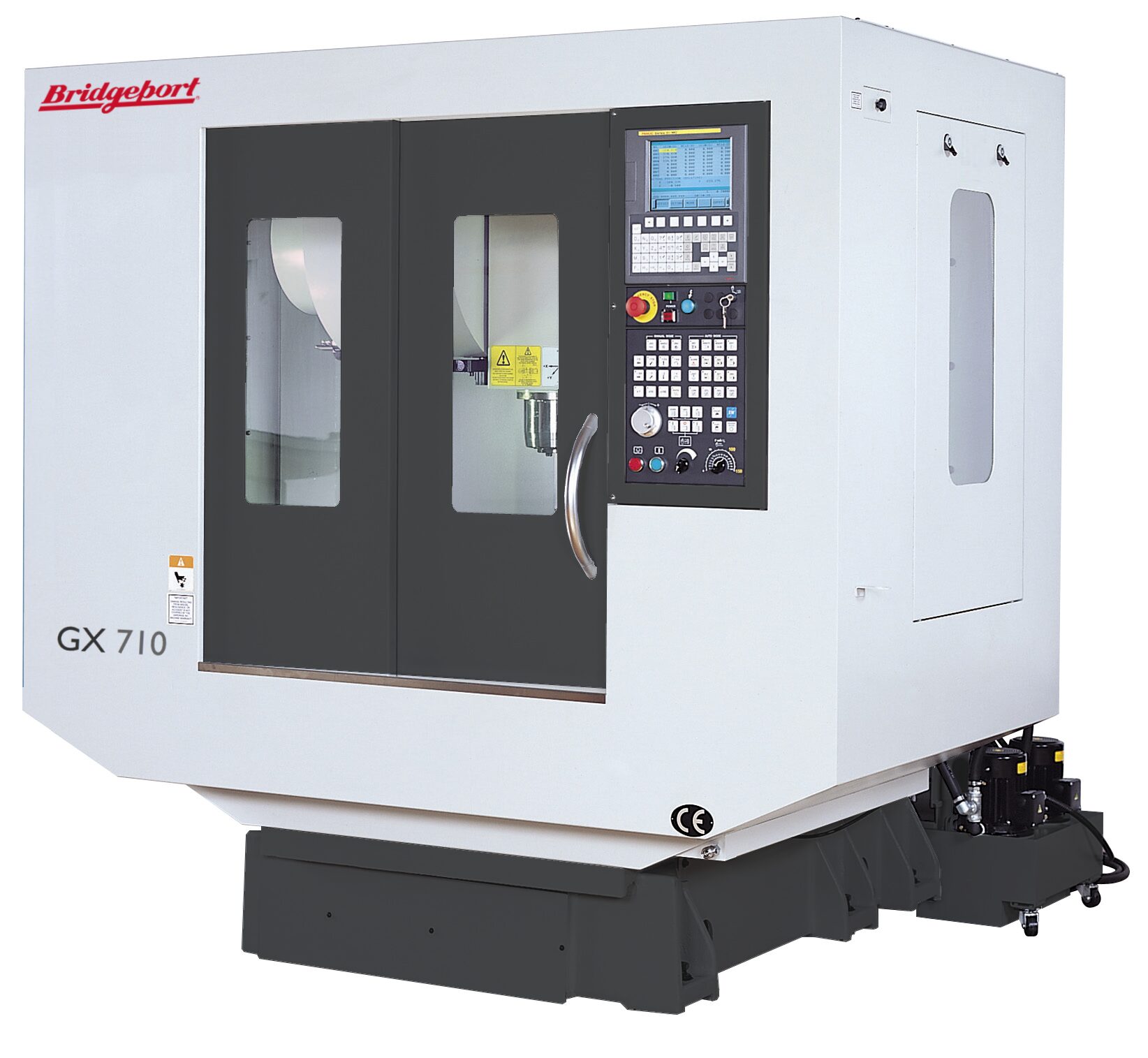

GX-Series

The Bridgeport® GX-Series Performance Vertical Machining Centers and Drill/Tap centers are designed for flexibility and throughput and built for a production environment. Ideal for both job shops and OEMs, these high-quality, highly-specified and rugged machines were developed for applications that require speed as well as accuracy. The unique design allows the machines to literally overlap one another to better utilize valuable floor space and to promote cell manufacturing and perfect for automation. Add some robots or a gantry system and you can increase your productivity with virtually no labor costs.

| GX710 | GX1000 | GX1600 | |

| Travel | |||

| X/Y/Z Axes | 710 x 400 x 430 | 1020 x 540 x 540 | 1600 x 700 x 635 |

| Spindle Nose to Table | 150 - 580 | 145 - 685 | 133 - 768 |

| Y-Throat Distance | 429 | 548 | 725 |

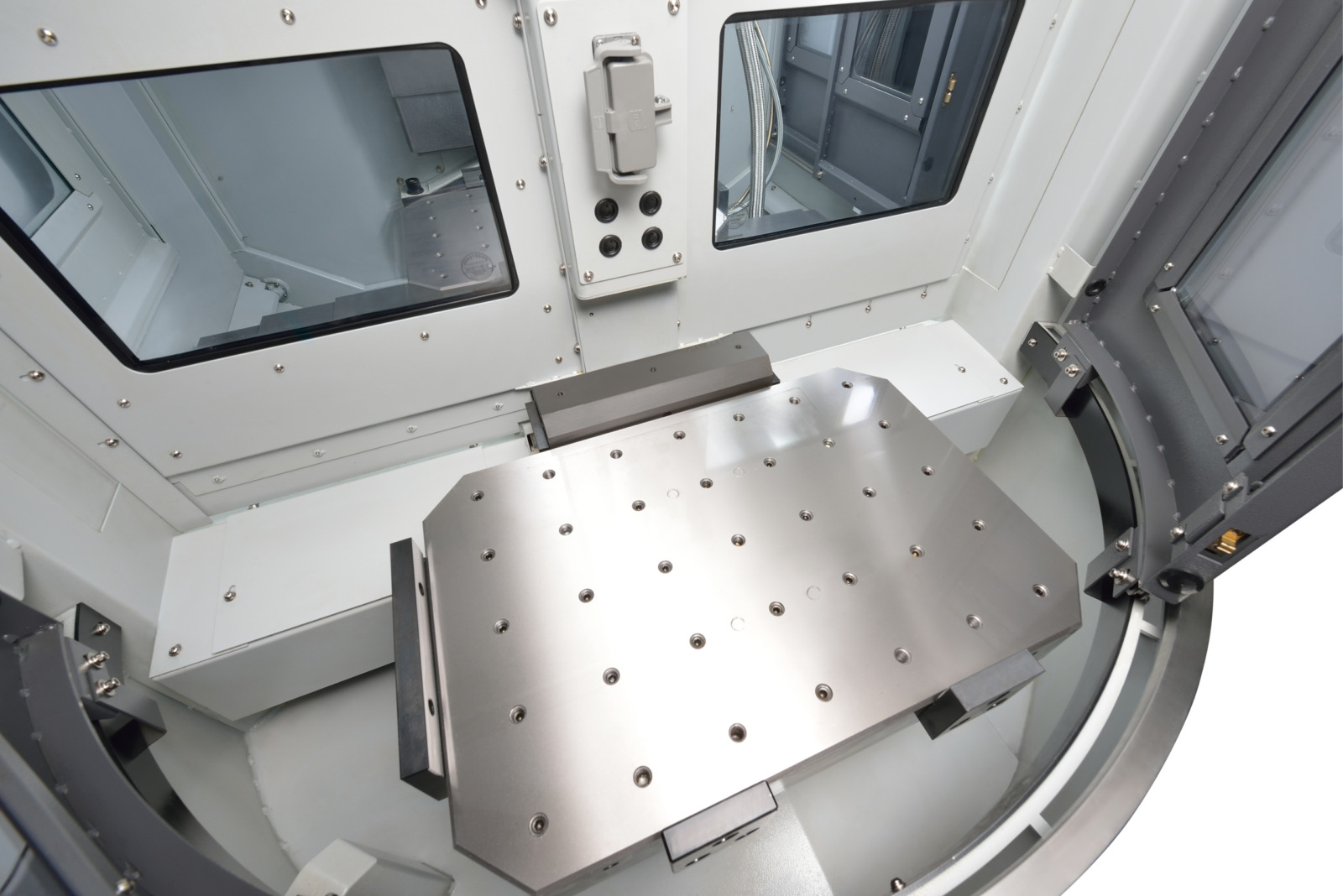

| Table | |||

| Table Size | 800 x 400 | 1120 x 540 | 1700 x 700 |

| Load Capacity | 300 Kg | 700 Kg | 1500 Kg |

| T-Slots (Width x No. x Size) | 14 x 3 x 125 | 18 x 5 x 100 | 18 x 5 x 125 |

| Spindle | |||

| Taper | No. 40 (BBT 40) | No. 40 | No. 40 |

| Transmission | DDS | DDS | DDS |

| Spindle Speed RPM | STD: 12000 (Grease) OPT: 12000 (Oil-Air) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 12000 (Oil-Air) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 12000 (Oil-Air) OPT: 15000 (Oil-Air) |

| Motor Power | 5.5kW/11kW (Cont./S3-15%) Fanuc | 11kW/18.5kW (Cont./S3-15%) Fanuc | 22kW/35kW (Cont./S3-25%) Fanuc |

| Max. Torque at Base Speed | 35N-m/70N-m (Cont./S3-15%) Fanuc | 52.5N-m/118N-m (Cont./S3-15%) Fanuc | 140N-m/180.5N-m (Cont./S3-25%) Fanuc |

| Automatic Tool Changer | |||

| Tool Capacity | STD: 24 OPT: 30 |

STD: 24 OPT: 30 |

STD: 30 OPT: 40 |

| Type/Tool Selection | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional |

| Pull Stud Type | BT/CAT/SK/ANSI 40 | BT/CAT/SK/ANSI 40 | BT/CAT/SK/ANSI 40 |

| Max. Tool Dia. | 80/150 | 80/150 | 75/150 (non-CE) or 130 (CE) |

| Max. Tool Length | 200 | 300 | 350 (non-CE) or 340 (CE) |

| Max. Tool Weight | 7 Kg | 7 Kg | 7 Kg |

| Tool Change Time (T-T) | 2.5 seconds | 1.6 seconds | 2.5 seconds |

| Axes Drives (X/Y/Z Axes) | |||

| Fanuc | 1.8kW/1.8kW/1.8kW | 1.8kW/1.8kW/1.8kW | 4kW/4kW/7kW |

| Siemens | 2.29kW/2.29kW/2.29kW | 3.05kW/3.05kW/3.05kW | 5.7kW/5.7kW/7.2kW |

| Ball Screws (X/Y/Z Axes) | |||

| Size | 25/25/30 | 40/40/40 | 45/45/45 |

| Pitch | 12/12/12 | 12/12/12 | 12/12/12 |

| Lubrication | Grease Central Lubrication | Manual Grease Central Lubrication | Manual Grease Central Lubrication |

| Linear Guideway (X/Y/Z Axes) | |||

| Type | Ball Guide | Ball Guide | Roller Guide |

| Size | 25/25/25 | 30/30/30 | 45/45/45 |

| Linear Ways | 2/2i/2 | 3/3/2 | 2/2/2 |

| Linear Guide Trucks | 4/4i/4 | 5/5/6 | 4/4/6 |

| Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication |

| Rapid Traverse Rate | 36 m/min | 36 m/min | 36 m/min |

| Accuracy (ISO 230-2) (X/Y/Z Axes) | |||

| Positioning | 0.01 | 0.01 | 0.014 |

| Repeatability | 0.005 | 0.005 | 0.007 |

| Positioning (w/ Scales) | 0.005 | 0.005 | 0.005 |

| Repeatability (w/ Scales) | 0.004 | 0.004 | 0.004 |

| General Specifications | |||

| Machine Overall Size (Width x Depth x Height) |

1975 x 2445 x 1945 - 2515 | 2955 x 2190 x 2713 | 3898 x 2754 x 2878 |

| Machine Weight | 3907 | 5500 | 9800 |

| Coolant Tank Capacity | 170 L | 360 L | 500 L |

| Air Requirement | 6 Kg/cm² | 6 Kg/cm² | 6 Kg/cm² |

| Power Requirement | 64 FLA/220V/3-Phase (Fanuc) 37 FLA/400V/3-Phase (Siemens) |

82FLA/220V/3-Phase (Fanuc) 43 FLA/400V/3-Phase (Siemens) 43 FLA/400V/ 3-Phase (Heidenhain) |

100 FLA/220V/3-Phase (Fanuc) 52 FLA/400V/3-Phase (Siemens) 65FLA/400V/3-Phase (Heidenhain) |

Bridgeport’s high quality, highly specified GX-Series Vertical Machining Centers (VMCs) are extremely compact and rugged mills; developed for applications that require both the utmost in speed and accuracy. V-Series machines are equipped with industry-leading features that enable speed, power, accuracy, and durability–all in a compact design and at an affordable price. GX-Series Vertical Machining Centers are rigid and reliable, consisting of a robust, one-piece cast iron base, heavy-duty linear guideways and ball screws, and many value-added standard features.

FANUC Control Features

- 10.4” Color LCD Display

- Linear/Circular/Helical Interpolation

- Programmable Data Input

- PCMCIA Card Slot

- Workpiece Coordinate System

- Manual Pulse Generator (Handwheel)

- Coordinate System Rotation

- Rigid Tapping

- Tool Life Management

- Tool Length Compensation

- Background Editing

- Ethernet Ready/USB Slot

- Additional Workpiece Coordinate System

- Manual Guide i

SIEMENS Control Features

- 10.4″ Color Display

- RJ45 Ethernet Port/Network Drive

- USB 2.0

- Compact Flash (CF) Interface

- Intuitive Jog Mode

- Tool and Workpiece Measurement

- Intuitive and Transparent tool Management

- Graphical Interactive Programming and Operation

- Mold Making Quick Viewer

- Transformation – Cycle800

- MDynamics – Mold and Die

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

FANUC Control Features

- 10.4” Color LCD Display

- Linear/Circular/Helical Interpolation

- Programmable Data Input

- PCMCIA Card Slot

- Workpiece Coordinate System

- Manual Pulse Generator (Handwheel)

- Coordinate System Rotation

- Rigid Tapping

- Tool Life Management

- Tool Length Compensation

- Background Editing

- Ethernet Ready/USB Slot

- Additional Workpiece Coordinate System

- Manual Guide i

SIEMENS Control Features

- 10.4″ Color Display

- RJ45 Ethernet Port/Network Drive

- USB 2.0

- Compact Flash (CF) Interface

- Intuitive Jog Mode

- Tool and Workpiece Measurement

- Intuitive and Transparent tool Management

- Graphical Interactive Programming and Operation

- Mold Making Quick Viewer

- Transformation – Cycle800

- MDynamics – Mold and Die

Heidenhain Control Features

- Contour Approach and Departure

- FK Free Contour Programming

- Program Jumps

- Fixed Cycles

- Coordinate Transformations

- Q Parameters

- Programming Aids

- Actual Position capture

- Verification Graphics

- Program Run Graphics

- Machining Time

- Returning to the Contour

- Datum Tables

- Preset Table

- Data Interfaces

- Tool Compensation

- Cutting Data Tables

- Constant Contouring Speed

- Parallel Operation

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

GX-Series Vertical Machining Centers can be found serving countless industries, including:

- Aerospace

- Pharmaceutical

- Automotive

- Large job shops & OEM