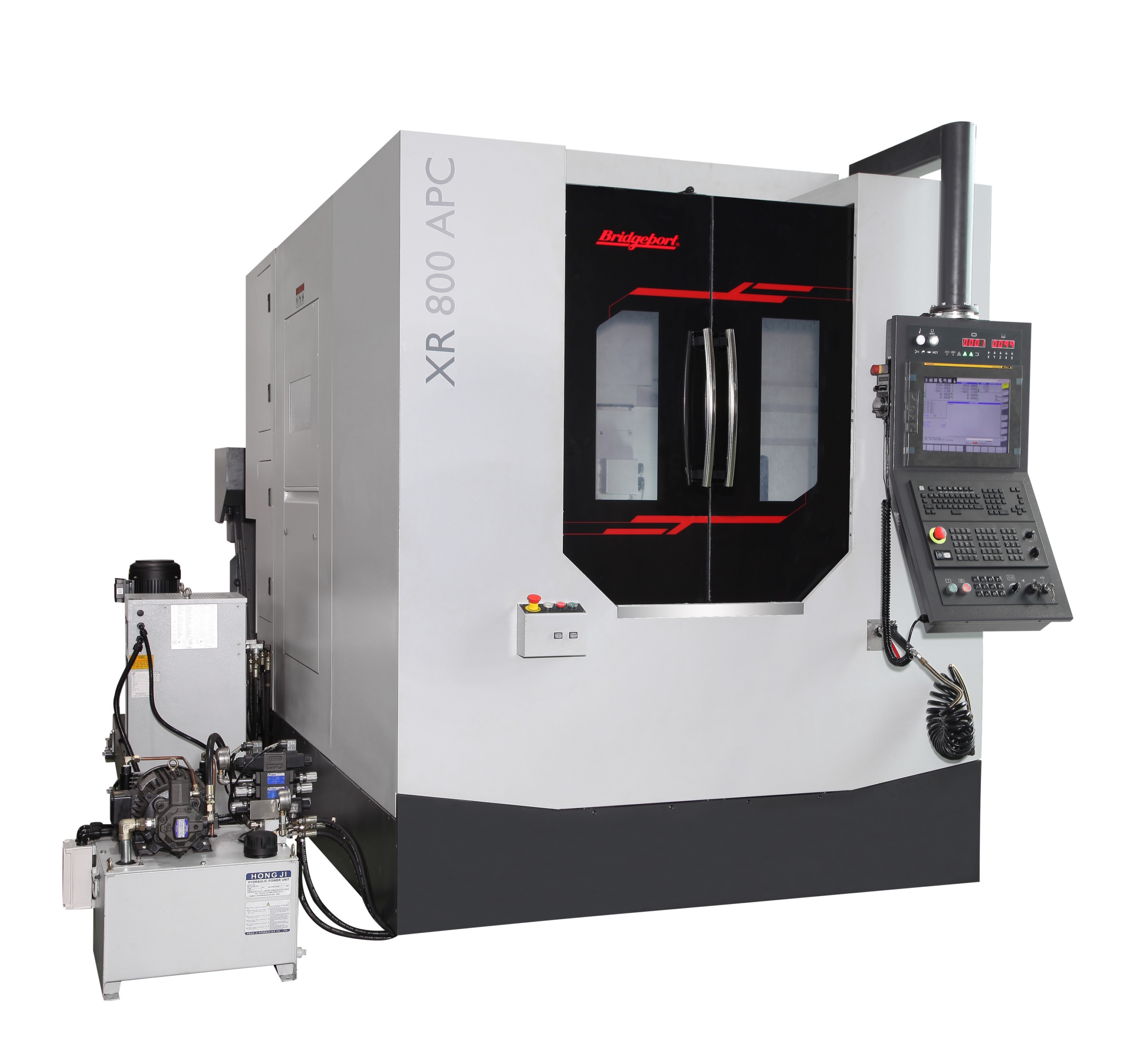

XR-Series

Built for the highest industry standards, the Bridgeport® XR-Series meets and exceeds the demanding metal cutting market. The XR-Series Vertical Machining Centers combine the successful experience and advanced design concept the Bridgeport brand provides with the precision machine tool Bridgeport advantage in a newly redesigned high performance machine. Ideal for those looking for increased capacity, processing efficiency and better all-around performance.

| XR600 | XR800 | XR800 APC | XR1000 | XR1320 | |

| Travel | |||||

| X/Y/Z Axes | 600 x 560 x 560 | 800 x 560 x 560 | 800 x 560 x 560 | 1020 x 610 x 610 | 1320 x 630 x 680 |

| Spindle Nose to Table | 150-710 | 150-710 | 150-710 | 100 - 719 | 150 - 830 |

| Y-Throat Distance | 581 | 581 | 581 | 628 | 638 |

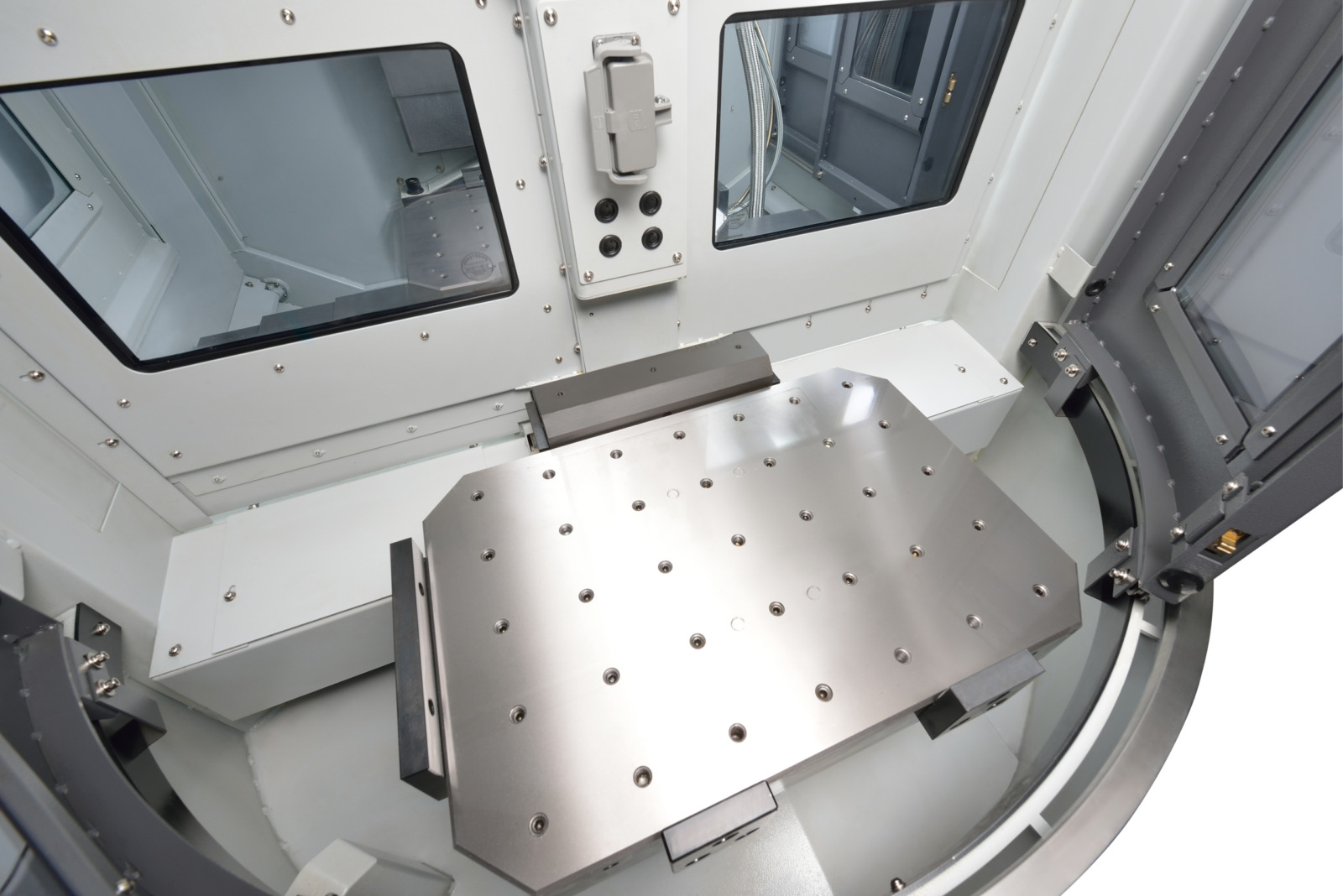

| Table | |||||

| Table Size | 750 x 560 | 950 x 560 | 850 x 500 | 1300 x 600 | 1400 x 600 |

| Load Capacity | 700 Kg | 900 Kg | 300 Kg x2 | 900 Kg | 1000 Kg |

| T-Slots (Width x No. x Size) | 18 x 5 x 125 | 18 x 5 x 125 | 18 x 5 x 100 | 18 x 5 x 100 | 18 x 5 x 100 |

| Spindle | |||||

| Taper | 40 | 40 | 40 | BBT 40 | BBT 40 |

| Transmission | DDS | DDS | DDS | DDS | DDS |

| Spindle Speed RPM | STD: 12000 (Grease) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 15000 (Oil-Air) |

STD: 12000 (Grease) OPT: 15000 (Oil-Air) |

| Motor Power | 11kW/18.5kW (Cont./S3-25%) Fanuc 95N-m/203.7N-m (S1/S6-25%) Heidenhain |

11kW/18.5kW (Cont./S3-25%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

11kW/18.5kW (Cont./S3-25%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

15kW/30kW (Cont./S3-15%) Fanuc 15kW/32kW (S1/S6-25%) Heidenhain |

15kW/30kW (Cont./S3-15%) Fanuc 15kW/32kW (S1/S6-25%) Heidenhain |

| Max. Torque at Base Speed | 70N-m/118N-m (Cont./S3-25%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

70N-m/118N-m (Cont./S3-25%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

70N-m/118N-m (Cont./S3-25%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

95.5N-m/191N-m (Cont./S3-15%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

95.5N-m/191N-m (Cont./S3-15%) Fanuc 95.5N-m/203.7N-m (S1/S6-25%) Heidenhain |

| Automatic Tool Changer | |||||

| Tool Capacity | STD: 30 OPT: 48 or 60 |

STD: 30 OPT: 48 or 60 |

STD: 30 OPT: 48 or 60 |

STD: 30 OPT: 48 or 60 |

STD: 30 OPT: 40 |

| Type/Tool Selection | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional | Swing Arm/Bi-Directional |

| Pull Stud Type | BT/CT/DIN (SK) | BT/CT/DIN (SK) | BT/CT/DIN (SK) | BT/CAT/SK/ANSI 40 | BT/CAT/SK/ANSI 40 |

| Max. Tool Dia. (Full Drum/Adj. Pocket Empty) | 75/150 (30T), 127 (48T & 60T) | 75/150 (30T), 127 (48T & 60T) | 75/150 (30T), 127 (48T & 60T) | Full: 75/Adj. Empty: 150 | Full: 75/Adj. Empty: 130 |

| Max. Tool Length | 300 | 300 | 300 | 300 | 300 |

| Max. Tool Weight | 7 | 7 | 7 | 7 | 7 |

| Tool Change Time (T-T) | 1.3~1.5 seconds | 1.3~1.5 seconds | 1.3~1.5 seconds | 1.5 seconds | 1.5 seconds |

| Axes Drives (X/Y/Z Axes) | |||||

| Fanuc | 4.5Kw/4.5kW/4.5kW | 4.5Kw/4.5kW/4.5kW | 4.5Kw/4.5kW/4.5kW | 3kW/3kW/4kW | 3kW/3kW/4kW |

| Heidenhain | 4.5kW/4.5kW/5.1kW | 4.5kW/4.5kW/5.1kW | 4.5kW/4.5kW/5.1kW | 4.5kW/4.5kW/4.5kW | 5kW/5kW/5kW |

| Ball Screws (X/Y/Z Axes) | |||||

| Size | 45/45/45 | 45/45/45 | 45/45/45 | 45/45/45 | 45/40/45 |

| Pitch | 12/12/12 | 12/12/12 | 12/12/12 | 16/16/12 | 16/16/12 |

| Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication |

| Linear Guideway (X/Y/Z Axes) | |||||

| Size | 35/45/45 | 35/45/45 | 35/45/45 | 35/45/45 | 34/45/45 |

| Linear Ways | 2/2/2 | 2/2/2 | 2/2/2 | 2/2/2 | 2/2/2 |

| Linear Guide Trucks | 4/4/6 | 4/4/6 | 4/4/6 | 4/4/6 | 6/4/6 |

| Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication | Grease Central Lubrication |

| Rapid Traverse Rate | 48m/min | 48m/min | 48m/min | 48m/min / 48m/min / 36m/min | 48m/min / 48m/min / 36m/min |

| Accuracy (ISO 230-2) (X/Y/Z Axes) | |||||

| Positioning | 0.009 (without scale)/0.004 (with scale) | 0.009 (without scale) 0.004 (with scale) | 0.009 (without scale) 0.004 (with scale) | 0.01 (without scale) 0.005 (with scale) | 0.01 (without scale) 0.005 (with scale) |

| Repeatability | 0.004 (without scale) 0.003 (with scale) | 0.004 (without scale)/0.003 (with scale) | 0.004 (without scale)/0.003 (with scale) | 0.005 (without scales) 0.004 (with scales) | 0.005 (without scales) 0.004 (with scales) |

| General Specifications | |||||

| Machine Overall Size without Conveyor (Width x Depth x Height) | 2726 x 3419 x 2941 | 2726 x 3419 x 2941 | 2726 x 3896 x 2941 | 2673 x 3026 x 2962 | 4000 x 3786 x 3225 (Hiahest) |

| Machine Weight | 6300 | 6900 | TBD | 7165 | 9200 |

| Coolant Tank Capacity | 400 L | 400 L | 400 L | 385 L | 450 L |

| Air Requirement | 6 Kg/cm² | 6 Kg/cm² | 6 Kg/cm² | 5.5 Kg/cm² minimum | 6 Kg/cm² minimum |

| Power Requirement | 89 FLA/220V/3-Phase (Fanuc) | 89 FLA/220V/3-Phase (Fanuc) | 89 FLA/220V/3-Phase (Fanuc) | 89 amp/220V/3-Phase (Fanuc) 56 amp/400V/3-Phase (Heidenhain) | 85 amp/220V/3-Phase (Fanuc) 84 amp/400V/3-Phase (Heidenhain) |

These robust machines offer exceptional stiffness and rigidity to deliver outstanding results in the most demanding production environments. They are particularly well-suited to machine exotic metals, such as Titanium and Nimonics (nickle- based alloys). To further increase productivity, XR-Series VMCs are configured for 4-axis machining with an optional interface and rotary table.

FANUC 0iMF Plus

- 15″ LCD Color Display

- Coordinate System

- Linear/Circular/Helical Interpolation

- Manual Guide i

- Cylindrical Interpolation

- Memory 1280m (512kb)

- Programmable Data Input

- Controlled Axes: 4

- PCMCIA Card Slot

- Least Input Increment – 0.001mm, 0.001 deg.

- Workpiece Coordinate System

- Fine Acc and Dec Control

- Addition of Workpiece Coordinate System 48 Pairs

- Servo Control HRV3

- Manual Pulse Generator (Handwheel)

- Backlash Compensation

- Coordinate System Rotation

- Mirror Image

- Polar Coordinate Command

- Automatic Acceleration/Deceleration

- Rigid Tapping

- Tool Life Management

- Rapid Traverse: Linear Cutting Feed: Exponential

- Tool Length Compensation

- Tool Offset Pairs, ± 6 Digits, 400 Pairs

- Tool Offset Memory C

- Part Program Storage Memory 2M

- Cutter Compensation C

- Number of Registerable Programs max. 1000

- Automatic Tool Length Measurement

- Self-Diagnosis Function

- Background Editing

- Alarm History Display

- Operation History Display

- Help Function

- Stored Pitch Error Compensation

- Custom Macro B

- Ethernet Ready/USB Slot

- Additional Workpiece

Heidenhain TNC 640 HSCI

- 15” TFT Color Flat Panel Display with Soft Keys

- Program Memory Solid State Disk (Minimum 21GB

- Interpolation: Straight Line in 4 Axes, Circle in 2 Axes, Helix: Combination of Circular and Linear Motion

- 0.5ms Block Processing Time

- Data Interfaces

- Heidenhain Conversational Programing as per ISO

- Tool Compensation

- Several Tool Tables with Any Number of Tools

- Cutting Data Tables

- Constant Contouring Speed

- Parallel Operation

Create Programs with Graphic Support While Another - Program is Running

- Contour Elements:

Line Segment, Chamfer, Circular Arc, Circle Center, CircleRadius,

Tangentially Connecting Circular Arc and Corner Rounding - Contour Approach and Departure

- FK Free Contour Programming

- Program Jumps

- Fixed Cycles

- Coordinate Transformations

- Q Parameters

- Programming Aids

- Actual Position Capture

- Verification Graphics

- Programming Graphics

- Program Run Graphics

- Machining Time

- Returning to the Contour

- Datum Tables

- Pallet Tables

- Touch Probe Cycles

- Preset Table

Conversational programming features offered on the CNC control is the CNC control builder’s standard product, which may not fully support all machine functions. It is recommended the end user reference the control system documentation, or contact the control manufacturer, for further details of use or customization.

Standard Features

- 12,000-rpm Spindle Speed

- CT40 or BT40 or SK 40Taper Spindles

- BIG-PLUS Face Taper Spindle

- High-Retention Draw Bar

- Thermal Compensation

- Chip Conveyor with Chip Washdown

- Cutter Air Blast

- Rigid Tapping

- 4th Axis Pre-Wiring

Optional Features

- 5th Axis Pre-wiring

- Transformer

- Tool/Part Probe (Wireless) (OMP 40-2 + OTS with OMI-2T)

- Column Riser 150mm

- Coolant Through Spindle, 1000 PSI Prep

- Surround Tool Coolant

- Linear Optical Scales (X/Y/Z Axes)

- Front Door Auto Door (Servo Motor type)

- Front Door Auto Door (Servo Motor type) with Light Curtain

- Tool Magazine Autodoor

- Tool/Part + OMI-2T Receiver

- Pre-wiring (Optical)

- Cutter Air Blast (Spindle Side)

- Spare M-Codes (8)

- Spindle Oil Chiller

XR-Series Vertical Machining Centers can be found serving countless industries, including:

- Aerospace

- Automotive

- Mold and Tool making

- Power Engineering

- Oil and Gas